Facilities

Our ultra-modern, climate controlled Longgang factory and logistic center offers a complete CNC solution. Operating state-of-the-art 3, 4 and 5-axis CNC machining centers and milling machines and specializing in high precision mechanical assembly, we provide our customers with a comprehensive range of metal processing and finishing solutions.

We also offer various value added services, including plating, honing, passivation, heat treating, welding, EDM, surface grinding, electroplating, tapping, laser cutting, anodizing MIL-A-8625 and MIL-DTL-5541 chemical filming.

Operating according to the international ISO 9002 and ISO 9001:2000 standards, we supply components for prominent OEMs in the medical, semi-conductor, automobile and telecommunication Industries.

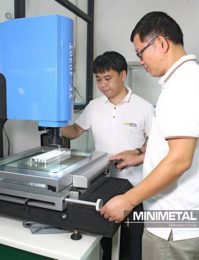

All manufacturing processes in MiniMetal are submitted to strict in-house QA verification, carried out by our seasoned production and QA engineers, logistic managers and administration workers, and supervised by Israeli CNC experts.

Utilizing an advanced priority manufacturing system, we closely manage and monitor every aspect of the process. Our engineering department has extensive knowledge of all products, processes and clients, ensuring perfect compliance to their requirements.

Using the most sophisticated testing equipment, our QA department identifies and approves all incoming raw materials and single-handedly inspects each product to identify all possible defects prior to shipping.

Combining advanced technological machining and human capabilities, we are able to manufacture complex parts for highly demanding applications according to each customer’s design specifications. It also enables us to offer improved performance, reduced total costs, higher production yield and faster time to market, making us a strategic manufacturing partner to our customers.

Good to Know

"Taking a holistic, hands-on approach, my team and I develop a working strategy for each project, seeing it through from conception to manufacturing. Leveraging over 15 years of CNC machining experience, as well as vast knowledge of the local market and cutting edge machinery, we can successfully meet even the strictest requirements and deadlines. And most importantly, we manage the whole process from right here in China. Living and working in Shenzhen for over a decade, you have my personal assurance that I will safely steer your project through all professional and bureaucratic challenges."

Boaz Shavit, CEO and Founder

Upload your design files here and we will inspect them and deliver a quick and free quote. Our quote form is highly secure.