Material Selection

Material selection plays a critical role in determining the overall quality and functionality of your parts, as well as the production process’ duration and cost.

Led by Israeli CNC experts, our team of seasoned production and QC engineers define the key characteristics required from the materials, according to your part or product objective and functionality. They then supervise the production process, to ensure the end result meets all the defined specifications.

Utilizing state-of-the-art 3, 4 and 5-axis CNC machining centers and milling machines, set in our ultra-modern Longgang factory and logistics center, we offer a wide variety of metal and plastic based materials, as well as custom materials.

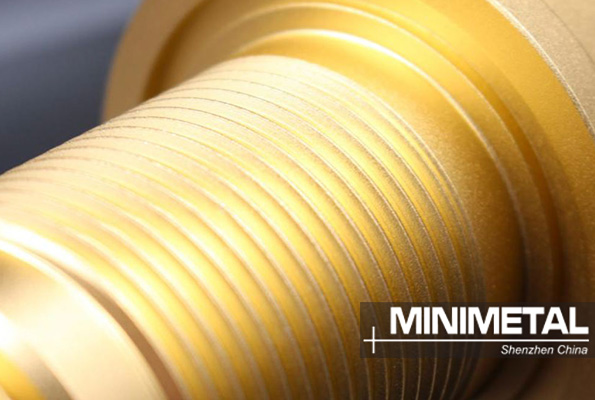

Metals

Upon selecting the type of metal for a project, there are three main factors to be taken into consideration, when trying to asses pricing and duration:

- The type of metal – a critical driver in determining a part’s overall cost, as the price gap between the different metals could reach hundreds of percent.

- Part size and geometry – determining the amount of metal required to produce the part, its size and geometry are key factors in determining the cost.

- Hardness level – soft metals machine easier than hard ones, reducing machining time and cost.

Plastics

Plastic materials could present a cheaper alternative to metal, unless the design demands higher rigidity levels. When deliberating the use of a plastic material, it’s important to consider that it might prove harder to adhere to tight tolerances, which could result in warping of the parts.

“The type of metal – a critical driver in determining a part’s overall cost, as the price gap between the different metals could reach hundreds of percent.

Part size and geometry – determining the amount of metal required to produce the part, its size and geometry are key factors in determining the cost.”

We Offer the Following Materials:

Good to Know

"Taking a holistic, hands-on approach, my team and I develop a working strategy for each project, seeing it through from conception to manufacturing. Leveraging over 15 years of CNC machining experience, as well as vast knowledge of the local market and cutting edge machinery, we can successfully meet even the strictest requirements and deadlines. And most importantly, we manage the whole process from right here in China. Living and working in Shenzhen for over a decade, you have my personal assurance that I will safely steer your project through all professional and bureaucratic challenges."

Boaz Shavit, CEO and Founder

Upload your design files here and we will inspect them and deliver a quick and free quote. Our quote form is highly secure.