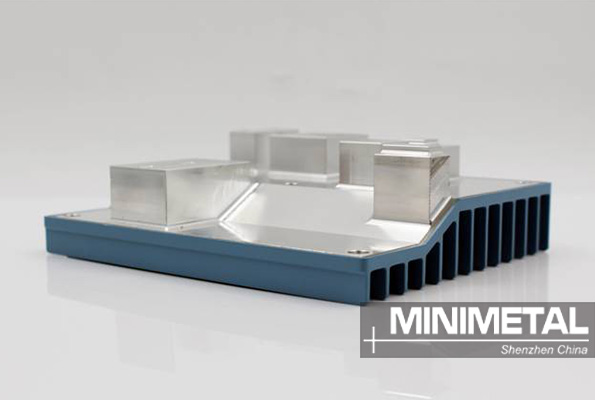

Heat sink

Heat sinks are an integral component in any thermal management solution, absorbing and dispersing heat to regulate temperature levels and prevent overheating in electrical components or systems.

MiniMetal provides OEMs with a diverse range of cost effective, custom advanced heat sink solutions constructed from copper or aluminum.

Our heat sink offering includes:

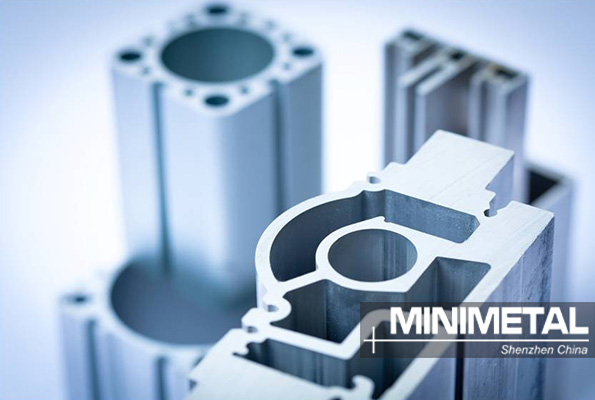

Custom Extruded Heat Sinks

As the most popular thermal management solution currently in use, extruded heat sinks are cost effective and easy to manufacture and customize, thereby ensuring quick order turn around.

The manufacturing process facilitates the complex fin design that encourages heat dissipation as heated aluminum billets are pushed or extruded through a die where the straight or cross-cut heat sink is manufactured. The process is also highly efficient for the manufacture of assorted natural convection solutions for higher power components and systems.

MiniMetal is able to promptly deliver a vast array of custom extruded heat sinks built to customer specifications. Our manufacturing capabilities, highly experienced staff and deep know-how in this expertise allow us to create the most complex heat sinks by providing a vast array of extrusion profiles, fin-to-fin spacing, and sizing to accommodate optimal thermal performance.

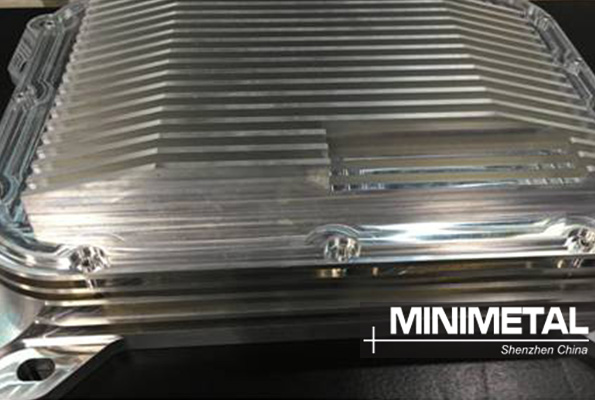

Cross Cut Heat Sinks

Cross cut heat sinks provide an optimal solution for applications where airflow is from multiple and varying directions; as the cross cut design specifications provide air flow from any direction. Similarly, performance is enhanced due to the large surface area and low pressure drop characteristics.

The manufacturing process involves standard extrusion of aluminum followed by the slotting process that creates rectangular pins.

MiniMetal produces a wide range of cross cut heat sinks to exacting standards that are cost efficient, light weight and optimize thermal resistance.

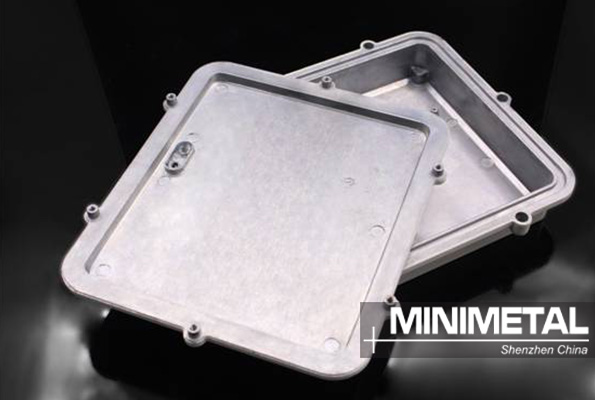

Die Cast Heat Sinks

Aluminum die cast heat sinks are highly cost effective, operationally efficient, and extremely robust. Another major advantage of die cast heat sinks is the ability to incorporate numerous features during the molding process, thereby reducing or machining and assembly costs.

Die cast heat sinks incorporate structural fin integration to encourage direct heat transfer to the environment. They also mitigate the requirement for additional copper plating costs as they provide electrical conductivity and can therefore be electrically grounded.

MiniMetal manufactures die cast heat sinks for any purpose – from basic circuit boards to the most complex communication and military electronics.

Round Pin Heat Sinks

Cold-forged round-pin heat sinks are the optimal choice for systems where airflow speed or direction may change during service. This is due to their omni-directional design resulting in minimum influence due to changes in airflow patterns.

The forging process confers additional benefits such as high strength, impurity-free and structurally sound (no air bubble or cavities) material, leak resistance, dimensional stability, and improved heat treatment predictability.

MiniMetal’s superior cold-forging capabilities are apparent in all the round pin heat sinks we manufacture.

Skived Heat Sinks

For high airflow, small space applications, skived copper heat sinks are the optimal heat dissipation solution. By combining the exceptional thermal conductivity characteristics of copper with skiving technology that enables the manufacture of incredibly thin fins that increase fin density and the aspect ratio, an optimal thermal conductivity solution is achieved.

The optimized fin surface area coupled with minimal tooling cost result in the cost effectiveness of skived heat sinks.

MiniMetal manufactures customized skived heat sinks to specification for all common skived fin heat sinks applications, including: telecommunication equipment, automotive components, computers and electronic components, household appliances, lighting, and industrial equipment and components.

Plate Fin Heat Sinks

Plate fin heat sinks are a proven, reliable and quiet heat extraction facilitator. The large, straight fins that populate the total surface area of the base plate encourage efficient heat convection.

Each of the multiple independent geometric parameters of the plate fin heat sink – fin thickness, height, length, spacing, and base length, width, thickness – can be varied according to specification.

MiniMetal has plate fin heat sink manufacturing capabilities to cost effectively satisfy any design type.